OUR TECHNOLOGY

Customized Solutions Built for Comfort

Every human limb is different, dynamic and changes over time, whether due to volume fluctuation, painful skin breakdown, or skeletal growth (in children). LIM Innovations offers a scalable and customizable solution to volume fluctuation by providing a dynamic interface that can be adjusted by both patients and clinicians.

Precise Adjustability

All LIM Innovations socket baseplates are fully adjustable. The Infinite Socket™ TF includes a built-in, adjustable anti-microbial brim. Unlike a conventional socket, amputees can tune the LIM Innovations micro-tensioning system on-the-go.

Personalized Suspension

LIM Innovations utilizes the same set of suspension options to those found in custom laminated sockets. Pick from Lanyard, Seal-In Suction, or Pin suspension depending on your preference.

High-Tech Fabrics

LIM Innovations works closely with high-performance shoe-wear and apparel companies to source the world’s most cutting-edge fabrics for the Infinite Socket.

Our proprietary all-weather fabrics enable us to bring a new degree of comfort, functionality, and usability to the field of prosthetics. We believe that if your sneakers get the best materials, so should your socket.

Carbon Fiber Struts

For major volume fluctuations, LIM Innovations lightweight thermoplastic carbon fiber struts can be quickly re-molded by a prosthetist months after the initial fitting, reducing the number of replacement sockets needed.

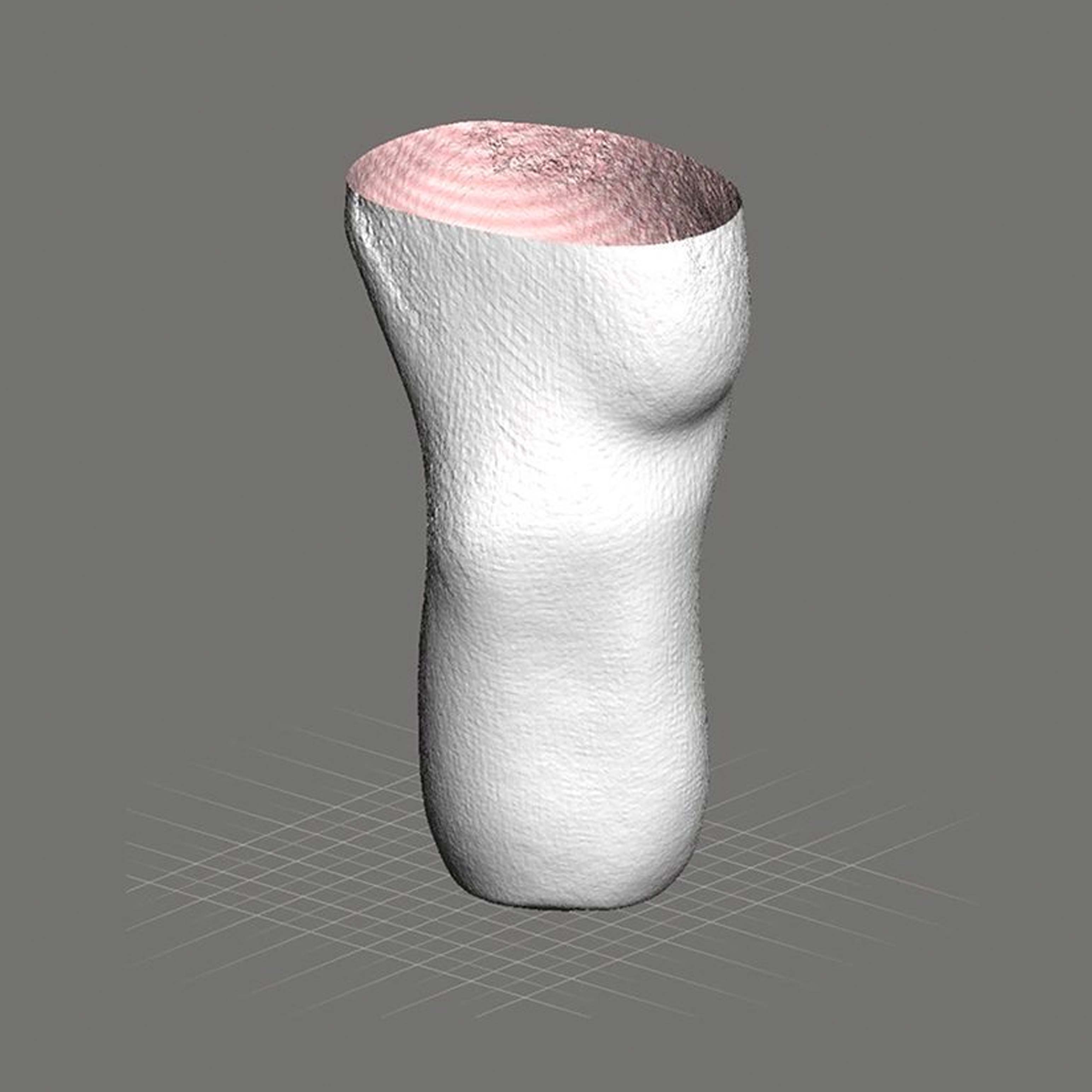

Innovative Manufacturing Process

LIM Capture is our proprietary process for achieving a well fitting, custom-molded socket without the requirement of an impression. Using only measurements and images, we develop a 3D, digital mold used to custom fabricate an Infinite Socket. With LIM Capture and the Infinite Socket’s design features, we eliminate the need for test sockets and decrease turnaround times to as little as 1 week.